EJOT-ATF

EJOT-ATF – Precision Fastening Solutions for the Next Generation of Electric Vehicles

EJOT-ATF, a strategic partnership between fastening specialists EJOT and ATF (Aerospace, Transportation, and Fasteners), is a trusted supplier of advanced fastening systems engineered to meet the evolving needs of electric vehicle (EV) manufacturing. Their innovation-driven portfolio is helping OEMs and Tier 1 suppliers solve key challenges in EV battery integration, lightweight construction, and structural safety.

With decades of experience in cold forming, machining, and assembly for automotive applications, EJOT-ATF delivers fasteners that ensure high-strength, durable joints in advanced lightweight materials — critical for today’s battery systems, body-in-white structures, and component housings.

Key Technologies Supporting EV Battery Systems:

-

EJOWELD® Friction Welding

Joins ultra-high-strength steel to aluminum — perfect for crash zones and battery enclosures. -

EVO PT® Screws

Self-tapping into thermoplastics with precise torque and pull-out strength for battery modules. -

TSSD® & EPPsys RSD®

Fasten lightweight foams and honeycombs like CFRP and EPP — strength without added weight. -

ALtracs® Plus

High-strength fastening straight into aluminum and magnesium for trays, casings, and more.

Whether in battery systems, powertrain components, or structural assemblies, EJOT-ATF’s fastening innovations are shaping the future of EV mobility, one high-performance connection at a time.

Parker Lord

Advanced Thermal Management & Adhesive Solutions for Next-Generation EV Batteries

Parker-Lord delivers cutting-edge thermal management and bonding solutions that address the most critical challenges in electric vehicle battery design. With a focus on safety, performance, and manufacturability, Parker-Lord’s CoolTherm® portfolio supports the full spectrum of EV battery architectures — from cylindrical and prismatic cells to complex cell-to-pack configurations.

Parker-Lord provides OEMs and Tier suppliers with customizable potting, encapsulants, gap fillers, and thermally conductive adhesives — engineered to enhance heat dissipation, structural integrity, and long-term reliability.

Key Battery Technologies from Parker-Lord:

-

CoolTherm® Potting & Encapsulants

Up to 4.0 W/m·K thermal conductivity with electrical insulation — protects components from shock, dust, and moisture. -

Thermal Gap Fillers

Silicone and urethane fillers smooth out surface gaps, boost heat transfer, and cushion against vibration — stress-free, stay-in-place performance. -

Structural Adhesives

Strong, thermally conductive bonds for dissimilar materials — cut fasteners, simplify assembly, and enable flexible battery designs.

From structural adhesives that eliminate the need for welding, to encapsulants that guard against thermal events, Parker-Lord’s thermal management and assembly solutions empower engineers to design safer, more efficient battery systems for the next generation of electric vehicles.

Parker-Lord: Solving thermal and structural challenges at the heart of electrification.

bdtronic

Precision Dispensing & Process Solutions for Next-Generation EV Battery Production

As the electric vehicle industry scales toward mass production, bdtronic—now part of the Dürr Group—stands at the forefront of advanced manufacturing technologies, delivering high-precision solutions that directly support the performance, safety, and longevity of EV batteries.

Specializing in dispensing, bonding, sealing, thermal management, and heat staking, bdtronic equips OEMs and battery system suppliers with the tools to manufacture safer, more reliable, and cost-efficient battery systems. Their solutions are trusted by global automotive leaders seeking to meet the demanding challenges of battery integration and next-generation design.

-

Dispensing & Bonding

High-precision adhesive application, plasma surface treatment, and potting/sealing solutions ensure durable bonding and protection of cells, modules, and housings. -

Thermal Management

Application of thermally conductive materials, foam encapsulation, and TIM dispensing technologies optimize heat dissipation and enhance battery safety. -

Joining Technologies

Robust heat staking and custom bonding techniques deliver strong, repeatable joins for battery assemblies and high-stress components.

From cell-to-pack bonding to battery control unit sealing and electric motor assembly, bdtronic’s systems are embedded at every critical junction of EV battery production. Their technologies support the evolution toward next-gen battery designs, including thermoplastic integration, hybrid module construction, and advanced cell chemistries.

As a process partner, bdtronic not only provides precision machinery but also works alongside customers to develop cost-effective, scalable, and custom-tailored solutions for unique battery architectures—helping EV manufacturers accelerate innovation while maintaining the highest standards of safety and quality.

ZELTWANGER

Leak Testing Solutions for a Safer, Smarter EV Battery Future

As electric vehicles scale to mass adoption, battery safety, performance, and reliability are under more scrutiny than ever. ZELTWANGER stands at the forefront of this critical mission, delivering high-precision leak testing technologies for every stage of the EV battery lifecycle — from prototype to full production, from individual cells to complete battery packs.

With decades of experience and innovation in automation, ZELTWANGER’s modular and scalable solutions ensure battery integrity, compliance, and end-of-line quality, empowering OEMs and Tier 1 suppliers to meet evolving performance and safety demands.

End-to-End Leak Testing for EV Battery Systems

Battery Cells

Whether cylindrical, prismatic, or pouch, ZELTWANGER provides reliable leak detection methods — including helium vacuum testing and electrolyte vapor detection — trusted by top global cell manufacturers.

Battery Modules & Components

From cooling systems and high-voltage connectors to pressure compensation elements and trays, ZELTWANGER ensures airtight performance across all battery subassemblies.

Complete Battery Packs

ZELTWANGER’s end-of-line (EOL) leak testing solutions verify the integrity of fully assembled packs using methods like mass flow, helium accumulation, and sniffing tests — with pinpoint accuracy even at ultra-low leak rates.

Innovative Technologies That Set ZELTWANGER Apart

-

Atmospheric Gas Analyzer

Detects electrolyte vapors without tracer gases or vacuum, capable of identifying microleaks down to 5 × 10⁻⁷ mbar·l/s — enhancing pack safety and environmental compliance.

-

ZEDcon Adapter Systems

A standardized, modular adapter range for fast, repeatable connections in manual and automated test stations.

-

PID-Controlled Air Filling

Advanced proportional-integral-derivative (PID) control for precise pressure control during air-based leak testing.

-

Scalable Automation

Solutions range from manual benchtop setups to fully automated lines with MES/ERP integration, part handling, and component marking.

Consulting, Customization & Turnkey Support

More than a testing equipment provider, ZELTWANGER acts as a development partner — supporting feasibility studies, prototype testing, and full system design. Every leak testing solution is customized to your leak rate, part geometry, and production needs.

From design validation to final inspection, ZELTWANGER’s holistic approach ensures your battery program is efficient, scalable, and future-ready.

ZELTWANGER – Ensuring leak-free performance, one battery at a time.

AkzoNobel

Single-Spray Powder Coatings for Safer, Smarter EV Battery Systems

AkzoNobel is transforming electric vehicle battery safety and manufacturing efficiency with its latest innovation: Resicoat® EV, a next-generation powder coating designed specifically for battery components. This breakthrough solution delivers high dielectric strength, thermal protection, and chemical resistance — all with a single-spray application, setting a new benchmark for productivity and performance in EV battery assembly.

Drawing on over 60 years of experience in electrical insulation and backed by a global presence in over 150 countries, AkzoNobel is helping battery manufacturers simplify production, reduce environmental risk, and meet the rising demand for safer and more sustainable EV technologies.

Key Advantages of Resicoat® EV Coatings:

-

One-Step Application

Full protection in a single spray — cuts labor, boosts speed, and streamlines production. -

Electrical Insulation

High dielectric strength prevents shorts and enhances battery safety. -

Thermal Management

Helps regulate pack temperature with efficient heat dissipation. -

Environmental Resistance

Shields components from thermal shock, moisture, and harsh chemicals. -

Component Versatility

Covers cooling plates, side plates, and enclosures with ease. -

Sustainability

Eco-designed to support clean energy and greener manufacturing.\

AkzoNobel – Coating the technologies of tomorrow with precision, protection, and purpose.

Sika

Powering Battery Performance with Precision Bonding, Sealing, and Thermal Management Solutions

Sika Automotive stands at the forefront of innovation in electric vehicle battery design and assembly, delivering high-performance solutions for bonding, sealing, and thermal management across the entire battery lifecycle — from cells and modules to full pack integration and fire protection.

With over a century of materials expertise and a global track record of success in the automotive sector, Sika is enabling OEMs and Tier 1 suppliers to overcome critical EV challenges — including thermal runaway prevention, lightweight construction, fast assembly, and fire safety compliance — all while simplifying manufacturing and improving structural reliability.

Complete Solutions from Cell to Pack

Sika’s technology portfolio supports every stage of EV battery development:

-

Thermally Conductive Adhesives & Gap Fillers

SikaBiresin® TC and Sikasil® deliver up to 3 W/m·K heat transfer with low abrasion and high chemical resistance — ideal for automated or manual use. -

Modular Assembly & Structural Bonding

Strong, lightweight bonds with no pretreatment. Epoxies, acrylics, STPs, and more bond metals and composites with ease. -

Pack Housing Assembly

Sikaflex® and CIPG sealants handle thermal expansion and chemicals — enabling fast, flexible cold assembly. -

Fire Protection

UL94-V0 rated adhesives and coatings that stop thermal runaway in its tracks — boosting EV safety. -

Lid Sealing & Serviceability

Watertight seals with Sikaflex® and SikaLastomer® — fast-curing, easy to assemble, and built for easy servicing.

Whether it’s improving heat transfer, reinforcing structural integrity, or enabling safe, fire-retardant battery systems, Sika’s end-to-end solutions help manufacturers charge forward with confidence. From early concept to mass production, Sika brings deep industry knowledge, global support, and customizable technologies that accelerate innovation in e-mobility. Charge your ambition with Sika – Engineering progress in every EV battery.

Elkem

Advanced Silicone Materials for Safer, Smarter Thermal Management & Battery Sealing

As electric vehicles become more powerful, compact, and fast-charging, Elkem is meeting the rising demand for advanced materials that enhance thermal management, fire protection, and sealing performance in battery systems. With over 70 years of silicone expertise and a global manufacturing footprint, Elkem is a trusted partner to OEMs and Tier 1 suppliers across the EV value chain.

Elkem’s comprehensive BLUESIL™ and CAF™ product lines offer high-purity, high-performance silicone solutions tailored for hybrid and electric vehicle (H&EV) battery packs. From gap fillers and adhesives to foams and gaskets, Elkem helps manufacturers improve thermal efficiency, extend battery life, and ensure safety under the harshest operating conditions.

Solutions Supporting EV Battery Innovation:

Thermal Management

Silicone gels, adhesives, and foams (0.4–3.0 W/m·K) manage heat, enable fast charging, and prevent thermal runaway — all with flexibility and easy processing.

Fire Protection

Naturally flame-retardant silicones with low smoke and toxicity — built-in safety for high-risk battery environments.

Battery Sealing

FIPG and CIPG gaskets ensure IP67/IP68-rated seals — protecting against moisture, dust, and vibration to boost pack lifespan.

Whether you’re designing next-generation EV battery packs, cooling systems, or sealing interfaces, Elkem helps you engineer for safety, longevity, and manufacturing efficiency — even under the most demanding thermal and environmental conditions.

Elkem – Driving the future of EV battery performance through smarter silicones.

NeoGraf Solutions

Lightweight Graphite Solutions for EV Battery Thermal Management

NeoGraf Solutions is redefining thermal management in electric vehicle batteries with lightweight, flexible graphite materials that replace bulky aluminum components. From BEVs and HEVs to drones, marine, and aerospace platforms, NeoGraf’s advanced solutions cool battery cells, prevent thermal propagation, and reduce weight — all while maximizing design flexibility and safety.

Key Technologies:

-

eGraf® HiTherm™ & NeoNxGen™

Maximize heat transfer, minimize weight and space — powerful thermal interface materials for tight EV designs. -

eGraf® SpreaderShield™

Thin, flexible graphite spreaders that stop thermal propagation and boost battery safety. -

GrafGuard®

Expandable fire-blocking flakes that activate during thermal events — passive protection made easy. -

Graf-X™

Conductive, high-strength graphene additives for advanced batteries and composites.

Whether you’re designing for automotive, marine, drone, or aerospace, NeoGraf’s graphite-based materials offer a compact, scalable alternative to metals, enabling high-performance batteries that are cooler, lighter, and safer.

NeoGraf – Thermal control without compromise.

ONE Our Next Energy

Our Next Energy (ONE) – U.S.-Built Battery Cells, Packs & Systems for a Sustainable, Scalable Future

Our Next Energy (ONE) is redefining energy storage for electric vehicles and grid applications with a vertically integrated, U.S.-based manufacturing model that delivers high-performance, sustainable, and domestically compliant battery solutions. From its flagship ONE Circle factory in Michigan, ONE is building a new standard for electrification by offering LFP battery cells, modules, packs, and advanced battery management systems, all engineered and produced entirely in the United States.

Key Technologies Supporting EV and Energy Storage Innovation:

-

314 Ah LFP Cell

The industry’s go-to LFP cell — safe, scalable, and U.S.-made. Fully ITC-eligible and EU battery passport ready. -

Aries™ Grid Module

Built for safety and performance, with top-tier thermal control and energy density for grid-scale storage. -

Grid BMS

In-house developed, 1,500V BMS with distributed monitoring for smarter, safer, high-voltage battery control. -

Aries™ LFP Pack

Michigan-built for commercial EVs, delivering exceptional energy density and proven long-cycle safety.

Built in the U.S. – Designed for the Future

Advantech International

Integrated Component Solutions for High-Performance EV Battery Systems

As electric vehicle technologies evolve, AdvanTech International delivers precision-engineered components that empower OEMs and Tier-1 suppliers to design safer, more efficient, and thermally optimized EV platforms.

Specializing in thermal management, structural fastening, motion sensing, and precision-machined parts, AdvanTech supports every layer of EV battery and drivetrain integration—from pack cooling to electric motor feedback systems. Their solutions are trusted by global automotive leaders navigating the demands of next-gen EV system design.

Thermal Management & Structural Hardware

Advanced battery cooling plates, high-efficiency heat sinks, and micro-fin aluminum solutions ensure stable temperature control and extend battery life under high-load conditions. Cold-formed busbars, terminal pins, and high-strength fasteners enable reliable electrical and mechanical connectivity.

Motion & Position Sensors

High-precision resolvers and angular sensors support real-time position tracking in e-axles, motors, and brake systems, ensuring accurate commutation and enhanced vehicle control.

Machined Powertrain Components

Precision gears, shafts, and mechanical assemblies are engineered to withstand high torque and voltage cycles across modern EV platforms, supporting drivetrain durability and power delivery.

From battery pack cooling and module fastening to motor control and sensing, AdvanTech’s component solutions are embedded across the critical interfaces of EV systems. Their technologies support advances in lightweighting, thermal control, and integrated electrification architecture.

As a trusted engineering partner, AdvanTech offers global sourcing, technical integration, and scalable manufacturing—enabling EV innovators to streamline development while achieving performance, safety, and cost targets.

ARNOLD

Engineered Fastening Solutions for Cutting‑Edge EV Battery & Structural Systems

ARNOLD Fastening Systems delivers precision-engineered fastening and joining technologies that empower OEMs and EV manufacturers to build safer, cleaner, and more reliable electric vehicles.

High‑Performance Fastening Technology

-

FlowForm® flow‑hole forming screws – enable fast, punch‑free frame and cover assembly

-

Strux® / Rivtex® and PIAS® clinch nuts – durable, non-detachable metal joining optimized for aluminum and steel battery frames

-

Load‑capacity thread‑forming screws & Eco‑Sert® inserts – high pull-out resistance and lightweight plastic-metal integration

Full‑System Integration & Lab‑Driven Engineering

-

Custom feeder and processing systems, turnkey fastening modules, and integrated testing in their in-house lab

-

Technical Cleancon process ensuring leak-tight, clean-fastening—critical for battery case sealing and functional reliability

Sustainability Through Innovation

With ACO₂‑Save, ARNOLD pioneers carbon-optimized fastener design and manufacturing:

-

Holistic carbon footprint analysis and co-optimization reduce part CO₂ emissions by up to 45%

-

Cold‑forming precision parts (Conform®) deliver high-quality, multifunctional components while cutting material waste and cost

From battery pack assembly to structural and thermal anchoring, ARNOLD’s fastening systems are an embedded element of EV design excellence. Their lab-validated technologies and sustainability-first strategy ensure EV platforms are built for performance, longevity, and environmental responsibility.

AIS

Fire & Thermal Protection Solutions for Safer, Lighter EV Battery Systems

As the electric vehicle market advances toward higher energy density and faster charging, AIS stands at the forefront of battery safety and thermal protection—engineering next-generation materials and systems that contain thermal runaway, protect structural integrity, and meet global safety standards.

Specializing in fire protection, thermal propagation control, and regulatory testing, AIS enables OEMs and battery system suppliers to design and validate EV battery packs that are lighter, safer, and more resilient. Their materials and in-house testing services are trusted by leading global manufacturers driving innovation in battery pack design and electrified mobility.

Thermal Propagation & Fire Containment

Ultra-lightweight materials such as ContraFlame® S-series and intumescent coatings prevent cell-to-cell thermal runaway and insulate against external fires, offering critical protection across modules, enclosures, and underbody components.

Battery Abuse & Homologation Testing

AIS operates Europe’s largest battery safety testing facility, offering full-scale abuse testing, material validation, and homologation services (UN38.3, R100, GB 38031) for cells, modules, and complete packs—accelerating safe time-to-market for EV programs.

High-Performance Insulation Materials

From thin, mica-free cell dividers to ultra-slim cooling plate barriers and high-voltage insulation for busbars and terminals, AIS develops precision materials that optimize thermal management and electrical safety without compromising on space or weight.

From prismatic and cylindrical cells to pack-level enclosures and cooling systems, AIS solutions are embedded at every critical interface in the EV battery architecture. Their fireproofing and insulation technologies support next-generation battery designs including high-energy chemistries, ultra-fast charging platforms, and integrated thermal management strategies.

As both a materials partner and testing specialist, AIS not only delivers cutting-edge safety components but also works closely with OEMs to co-engineer, certify, and deploy scalable solutions that meet evolving regulatory and performance demands—empowering the EV industry to innovate safely, efficiently, and responsibly.

AVL

Holistic Battery Testing & Development Solutions for Advanced EV Platforms

As EV battery systems become more powerful and complex, AVL List leads in delivering comprehensive testing, simulation, and engineering solutions that ensure safety, performance, and rapid market readiness.

With over 20 years of electrification expertise, AVL empowers OEMs, battery manufacturers, and system integrators to develop next-generation EV architectures and battery packs with confidence.

From Cell to Pack: Complete Battery Testing Systems

AVL’s modular Battery Cell TS, Module/Pack TS, and bi-directional E-STORAGE platforms deliver precise electrical and thermal evaluation at every scale—cell to full-pack—backed by high-throughput automation and up to 1,500 A current capacity

Accelerated Thermal Conditioning & Safety

Innovative ACORA direct coolant-conditioning racks reduce test time by up to 60%, while AVL Stingray™ fire suppression systems protect labs by targeting thermal runaway sources quickly and efficiently

HV Integration & E‑Drive Validation

Their HV System TS™ supports safe evaluation of high-voltage battery systems, e‑motors, inverters, and full e‑axles, simulating real-world environmental and operational conditions for system-level validation

Digital Twins, Automation & Analytics

The all‑inclusive LYNX 2™ automation software, paired with PUMA 2™ lab-management and data analytics engines, enables repeatable, scalable testing workflows—accelerating R&D and enabling predictive insights

Tailored Battery Engineering & Lifecycle Tools

AVL also offers bespoke battery development services—from concept design to manufacturing ramp, digital battery passports and AI-driven lifetime prediction—helping OEMs reduce cost, improve safety, and enhance sustainability

From initial battery cell validation to full-system electrification testing and lifecycle analytics, AVL’s integrated solutions are at the forefront of EV battery innovation. Their labs, systems, and engineering services are used by top automakers and Tier-1s worldwide—helping deliver safer, higher-performing EV platforms faster and more reliably.

ELANTAS

Innovative Insulation & Protection Systems for EV Battery and Power Electronics

As electric and hybrid vehicles push boundaries in power density and reliability, ELANTAS North America—part of the ALTANA Group—provides essential insulating and protective materials that enhance safety, efficiency, and longevity across EV battery, motor, and powertrain systems.

Specializing in wire enamels, potting compounds, conformal coatings, and thermal interface materials, ELANTAS equips OEMs and Tier‑1 suppliers with solutions that safeguard against electrical stress, thermal challenges, and environmental degradation. Their products are trusted by global automotive leaders developing advanced EV architectures.

Electrical & Thermal Insulation Materials

-

Flexible electrical insulation: Slot liners, phase insulation, and slot closure films protect motors and generators from electrical failure under extreme conditions.

-

Wire enamels & impregnating resins: Enhance coil durability and performance in high-voltage, high-heat e-mobility environments.

-

Thermal interface & potting compounds: ELAN‑tim® and Elan‑tron® systems manage heat in converters and battery modules, improving thermal conductivity and safeguarding electronics.

Conformal Coatings & Environmental Protection

Robust coatings like Bectron®, Conathane®, and CONAP® protect PCBs, sensors, and electronic assemblies from moisture, dust, and harsh operating conditions—ensuring long-term reliability in EV power electronics

From motor stator insulation and busbar protection to thermal management in battery packs and conformal protection of controllers, ELANTAS systems are embedded across the EV powertrain and battery ecosystem. Their focus on innovative materials and localized service enables OEMs to achieve efficient, safe, and durable vehicle platforms.

As a materials partner, ELANTAS collaborates with customers to co-engineer solutions aligned with performance, safety, and EV electrification objectives—supporting the next generation of sustainable mobility.

STANLEY

Advanced Fastening & Safety Solutions for Next-Generation EV Battery Assembly

As the electric vehicle industry scales toward mass production, STANLEY® Engineered Fastening provides advanced joining and protection technologies that enable the safe, efficient, and high-speed assembly of next-generation EV platforms.

With a comprehensive portfolio of fastening systems, thermal management components, and smart automation solutions, STANLEY equips OEMs and Tier-1 suppliers with the tools to meet the challenges of electrification—delivering precision, reliability, and innovation from battery packs to full vehicle structures.

Precision Fastening & Joining Solutions

-

Mechanical Joining for Mixed Materials: Self‑pierce rivets, no‑hole stud welding, clinching, blind rivets, and torque‑controlled screws for lightweight assemblies and multi‑material chassis & battery housings.

-

High‑Voltage & Grounding Hardware: Specialized fasteners, sealing rivets, terminal protectors, and plastic clips engineered for high-current stability, vibration resistance, and thermal expansion management

Thermal & Pressure Management in Battery Packs

STANLEY’s engineered solutions, such as thermal-fin separators and vent-plugs, actively control temperature, thermal propagation, and internal pressure—mitigating risks of thermal runaway while improving pack longevity. Their experts also provide webinars on EV thermal and pressure management, underscoring industry-leading technical knowledge.

Smart Assembly & Process Automation

Integrated tool systems, feeders, and automated fastening cells enable scalable EV battery production with full process traceability. STANLEY’s digital fastening platforms provide torque and angle monitoring, error-proofing, and real-time data feedback—accelerating production and ensuring consistent quality.

From cell module fastening to high-voltage busbar attachment and thermal runaway venting, STANLEY’s engineered systems are embedded at every level of EV battery and chassis assembly. Their solutions support the industry’s move toward modular, lightweight, and thermally controlled battery designs for the next generation of electric vehicles.

Neural Concept

AI-Driven Simulation for Faster, Smarter EV Battery Innovation

As electric vehicle development accelerates, Neural Concept brings the power of deep learning to engineering design—revolutionizing how EV batteries and components are developed, tested, and optimized.

Their flagship platform, Neural Concept Shape, enables automotive OEMs and Tier-1 suppliers to reduce simulation time from hours to milliseconds, accelerate design cycles, and enhance performance across battery packs, cooling systems, and lightweight structures.

By integrating real-time 3D deep learning into the engineering workflow, Neural Concept empowers teams to unlock high-performance EV architectures—faster, smarter, and with fewer iterations.

Battery Thermal Management

AI-powered surrogate models enable rapid simulation and optimization of battery cooling systems. Engineers can explore thousands of design variants for cold plates, manifolds, and cooling channels in minutes—achieving significant improvements in heat dissipation and system efficiency without time-consuming CFD.

Use Case: A leading Tier-1 achieved a 30% thermal efficiency gain and reduced development cycles by 6 weeks through AI-driven cooling design optimization.

Structural Design & Crash Optimization

Neural Concept Shape enables high-fidelity predictions of stress, deformation, and crash response across complex battery housings and protective enclosures. Deep-learning models trained on FEA simulations provide near-instant results that empower lightweighting and material selection—without sacrificing safety or compliance.

Design Exploration & Concept Engineering

Designers and engineers can evaluate thousands of geometry variants instantly—with actionable insights into physical behavior, manufacturability, and system performance. This drives faster innovation in EV platforms, from early-stage topology optimization to detailed parametric studies.

Integrates seamlessly into CAD/CAE tools like CATIA, NX, Ansys, and Fluent—enabling plug-and-play AI acceleration across established workflows.

From battery cooling plates and structural enclosures to high-voltage insulation and pack architecture, Neural Concept’s 3D deep learning models are transforming every aspect of EV battery system design.

Their cloud-native platform supports multi-physics domains—including thermal, structural, fluid, and electromagnetic simulation—ensuring optimal performance across the entire battery lifecycle.

As a trusted technology partner, Neural Concept works alongside OEMs to implement custom AI workflows tailored to unique battery architectures and electrification strategies—accelerating development while reducing physical testing and simulation costs.

SEKISUI

Advanced Thermal Management & Safety Materials for High-Performance EV Battery Systems

As EV battery systems evolve to support higher energy densities, faster charging, and stricter safety standards, Sekisui Chemical delivers cutting-edge materials that optimize thermal control, flame resistance, and structural protection across the battery platform.

With a global footprint and vertically integrated R&D and manufacturing, Sekisui collaborates with leading OEMs and Tier-1 suppliers to co-develop next-generation battery packs that are safer, lighter, and more thermally stable—ready for mass electrification.

Thermal Interface Materials (TIMs)

Sekisui’s CGW® Thermal Gap Filler series offers high-performance, liquid-dispensed TIMs with thermal conductivities ranging from 2 to 4.5 W/m·K. These gap fillers are engineered for use between battery cells and cold plates, supporting precise automated dispensing and excellent wet-out under compression.

-

Grease-type gap fillers provide low thermal resistance with excellent long-term stability.

-

Adhesive-type variants offer combined thermal transfer and bond-line control, reducing parts and assembly steps.

-

Fully validated for pack-level vibration, thermal shock, and electrical reliability across major EV platforms.

Flame-Retardant Battery Enclosure Sheets

Sekisui’s thermoplastic composite sheets (e.g., Softlon™ FR-ND) replace heavy aluminum or steel covers with lightweight, flame-blocking polymer solutions that meet UL94 V-0 and ECE R100.02 fire safety standards.

-

Weight savings up to 61% over traditional metal housings.

-

Exceptional insulation, compressibility, and sealing properties for pack exteriors and internal module dividers.

-

Maintains structural integrity during thermal runaway and external fire exposure.

These materials are ideal for cell-to-cell barriers, battery case lids, underbody shields, and thermal propagation containment layers.

Vibration, Acoustic, and Multifunctional Material Solutions

Sekisui’s cross-linked polyethylene (PE) and polyurethane (PU) foams offer lightweight, flame-resistant solutions for managing vibration, acoustic damping, and thermal insulation within EV battery packs. Designed to reduce mechanical stress during vehicle operation, these foams are customizable in thickness and form, supporting safe and stable battery performance.

ViscoTec

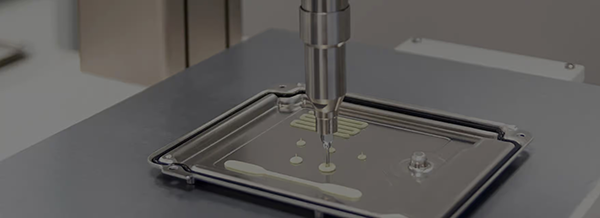

Precision Dispensing & Sealing Solutions for Next‑Generation EV Battery Production

As electric vehicle production scales to meet global demand, ViscoTec offers industry-leading dispensing, dosing, and sealing technologies that enhance battery safety, efficiency, and reliability—serving OEMs and battery manufacturers with the precision required for cutting-edge EV systems.

Electrolyte Filling & Cell Potting

ViscoTec’s vipro‑PUMP EV enables pressure‑controlled electrolyte filling of cylindrical and prismatic hard-case cells. This one-step evacuation-and-fill approach ensures bubble-free delivery, consistent pressure, and sealed performance across cell formats

Gap‑Filler & Thermal Paste Dispensing

Using volumetric dispensing with endless‑piston pumps, ViscoTec applies thermally conductive pastes and gap fillers (1- & 2‑component) accurately between cells and cooling plates—supporting high charging rates and thermal stability without air entrapment

Module & Pack Sealing

Highly controlled dispensing of adhesives and sealants ensures tight housing seals in battery modules and BMS enclosures. The systems support complex geometries and eliminate heat stress from welding processes

Potting, Bonding & Impregnation

ViscoTec’s ViscoDuo‑VM progressive‑cavity dispenser enables bubble‑free 2‑component resin mixing and precise potting between cells. A collaboration with Von Roll validated its transition from lab to production for safe electrical insulation and thermal performance

Enduring, Versatile Systems

Configured with ceramic rotors and vacuum‑fed supply modules, ViscoTec’s dispensers handle abrasive, reactive, and high-viscosity fluids (up to 7 million mPas) with repeatability >99 % and no drip-off—ideal for demanding EV processes.

From cell‑to‑pack, ViscoTec’s systems ensure exact fluid delivery—from electrolyte and adhesives to potting compounds and sealants—supporting fast, clean, and reliable EV battery assembly. Their turnkey solutions include process engineering, digital flow control, and seamless automation integration.

Joyson Safety Systems

High-Voltage Battery Safety & Crash Protection Systems for Advanced EV Architectures

As electric vehicles evolve toward higher energy density and voltage platforms, Joyson Safety Systems delivers critical safety technologies that protect occupants, emergency responders, and vehicle systems from high-voltage hazards.

With deep expertise in crash sensing, electrical isolation, and integrated protection systems, Joyson supports OEMs worldwide with proven solutions designed to meet the most demanding EV safety standards.

Pyrotechnic Battery Disconnect (PBD)

Joyson’s award-winning PBD device provides instantaneous high-voltage disconnection during crash events or electrical faults. Activated by vehicle crash sensors or thermal triggers, the PBD physically severs the power circuit in under 4 milliseconds—eliminating arc flash risk and enabling first responder access.

-

Integrated arc suppression and fuse function

-

Compact and scalable for 400V and 800V systems

-

Approved by multiple global OEMs for series production

Recipient of the Automotive News PACE Award and CLEPA Innovation Award

Battery Crash Detection & HV Circuit Isolation

Joyson’s high-speed sensing modules integrate directly into battery management and vehicle safety networks to coordinate rapid HV disconnect, thermal event response, and post-crash diagnostics. These systems help ensure regulatory compliance (e.g., UNECE R100, FMVSS 305) while reducing risk of electric shock or thermal runaway escalation.

Occupant & Structural Safety Integration

In addition to electrical safety, Joyson Safety Systems provides full passive safety coverage for EVs, including:

-

Airbags and steering systems optimized for altered EV crash dynamics

-

Seatbelt systems and restraint controllers with pre-crash and thermal event logic

-

Crash impact sensors tuned to trigger HV isolation and occupant protection simultaneously

From pyrotechnic battery disconnect units to holistic EV crash sensing strategies, Joyson Safety Systems offers a robust safety platform built for modern electric vehicles. Their solutions are embedded in dozens of EV programs worldwide—enabling OEMs to meet growing safety expectations while optimizing vehicle architecture and response protocols.

As a global partner with R&D, engineering, and production capabilities across 22+ countries, Joyson collaborates directly with EV manufacturers to deliver tailored, tested, and future-ready solutions for the electrified road ahead.

Plasmatreat

Openair-Plasma® Surface Pretreatment for Next‑Generation EV Battery Systems

As EV manufacturing moves toward greater automation and sustainability, Plasmatreat pioneers atmospheric and low-pressure plasma solutions that enhance battery production quality, safety, and longevity. Their advanced Openair‑Plasma® and PlasmaPlus® systems are engineered for cleaning, surface activation, and functional nano-coatings—optimizing every stage from cell prepping to full-pack assembly and corrosion resistance.

Cell & Module-Level Plasma Cleaning & Activation

Plasmatreat’s inline plasma treatment units precisely remove oils, oxides, and residues from cylindrical and prismatic cells, prepping surfaces for seamless adhesive bonding or wire-laying. This micro-fine cleaning improves adhesion, thermal contact, and electrical insulation—critical for reliable, high-speed cell-to-module assembly.

Enhanced Bonding & Sealing with PlasmaPlus® Coatings

Using Openair-Plasma® followed by PlasmaPlus®, battery housing edges and module frames receive ultra-thin protective coatings—optimizing adhesive wetting, corrosion resistance, and sealing integrity. The method replaces VOC-heavy wet-chemistry processes with eco-friendly, inline automation.

Functional Surface Tailoring for Thermals & Insulation

Plasma treatments can create hydrophilic or hydrophobic layers, shift electrical insulation properties, and support selective wear protection or barrier coatings—enabling custom functionalization of housing, busbars, and cooling interfaces.

Manufacturing Efficiency, Safety & Sustainability

-

VOC-free, CO₂-neutral process using only compressed air and power

-

High-speed inline integration, no vacuum chambers, easily retrofitted

-

Better quality control, reduced rejects, lower production costs

-

Global expert support through North America, Europe, and Asia offices

As a strategic process innovation partner, Plasmatreat collaborates with OEMs and battery system integrators to implement turnkey plasma stations, automation packages, and process optimization—enabling next-gen EV architectures to deliver reliability, performance, and regulatory compliance at scale.

Intertek

Comprehensive Testing & Certification Solutions for Next-Generation EV Battery Systems

As electric vehicle adoption accelerates, Intertek empowers OEMs, battery developers, and Tier‑1 suppliers with world-class testing, certification, and advisory services—ensuring EV battery packs, cells, modules, and charging systems meet global safety, performance, and sustainability standards.

Battery Testing & Abuse Certification

Intertek offers full-spectrum cell-to-pack testing—including cycle life, thermal shock, humidity, vibration, crush, nail-penetration, overcharge, short-circuit, and fire-abuse tests. Their labs, accredited in key automotive hubs like the US, EU, and Asia, support compliance with UL 2271/2580, IEC 62133, UN 38.3, ISO 12405, SAE, ECE R100, and LV 123/LV 124 standards

EVSE & High‑Voltage Charger Compliance

From onboard chargers to charging plugs and EVSE infrastructure, Intertek validates safety and EMC using UL, SAE J1772, IEC 61851/62196, UL 2594, UL 2251, FCC, and EN standards—supporting global market entry for high-voltage components

Abuse & Fire Response Evaluation

Specialist labs perform abuse, fire endurance, and forensic ‘cell-teardown’ services—delving into failure mechanisms and resilience for advanced battery systems. High-power lithium-ion and HEV battery consulting also includes cell autopsy and thermal-chemical analysis

Performance Benchmarking & Lifecycle Modeling

Advanced battery performance testing includes HPPC, calendar and cycle life assessments, BMS simulation, prototype benchmarking, eco-labeling, and digital lifecycle modeling—helping OEMs quantify performance and accelerate R&D cycles

Sustainability, Regulatory & Advisory Solutions

Beyond technical testing, Intertek’s sustainability services include LCA, carbon footprinting (CarbonClear™, CarbonZero™), second-life certification for stationary storage, supply chain auditing, and regulatory support across UN, EU, US, and global jurisdictions

From critical safety validation to electrical compliance, sustainability assurance, and high-voltage reliability, Intertek is the trusted partner at every stage of EV battery and charging system development. Their global labs, certifications, and expert teams help OEMs bring safe, reliable, and compliant EV solutions to market—on time and in line with evolving regulations.

EVONOMY Group

Ecosystem-Driven Engineering Acceleration for Next-Gen EV Architectures

As the electrification race intensifies, Evonomy empowers OEMs and Tier‑1s to design, specify, and validate future-ready EV platforms—faster and more cost-effectively. With a curated global network of 700+ suppliers, Evonomy functions as an engineering catalyst, helping leading automotive teams architect cutting-edge battery, electrification, and software-defined vehicle systems.

Through deep domain expertise in battery packs, BMS, power electronics, and vehicle architecture, Evonomy provides impartial solution guidance that drives technical clarity, supplier alignment, and program acceleration.

E/E Architecture & System Co-Design

Evonomy partners with OEMs and Tier-1s to co-create scalable vehicle and system-level architectures across domains including:

-

Battery platforms (48V to 800V+)

-

Zonal & central compute

-

Power distribution units, DC/DC converters, inverters, and OBCs

-

Battery materials, coatings, cabling & harnesses

Component & Technology Selection

Evonomy helps teams identify and recommend the best-fit components across multiple EV subsystems:

-

Battery modules and (w)BMS

-

Traction inverters (SiC, GaN, IGBT)

-

Motors, eDrives, eAxles

-

Simulation tools, vision stacks, and EDA software

Selections are based on OEM-defined criteria including cost, performance, timing, and manufacturability.

Accelerating Innovation with Ecosystem Intelligence

Evonomy’s role as an impartial connector delivers unique advantages:

-

Access to pre-qualified EV suppliers across electrification, software, and autonomous systems

-

Hands-on co-architecture and technical matchmaking

-

Average time savings and cost reductions per project through reduced iteration cycles and faster sourcing

From battery system specification and inverter selection to full E/E strategy development, Evonomy provides the technical expertise and ecosystem reach needed to bring next-generation EV platforms to market—faster, smarter, and with total alignment.

Constellium

Lightweight Aluminum Solutions Powering Next‑Gen EV Battery Systems

As electric vehicles strive for longer range, faster charging, and enhanced safety, Constellium delivers advanced aluminum solutions—from cell connectors to full enclosures—that elevate performance, durability, and sustainability.

Constellium’s offerings are trusted by leading OEMs, including Audi, BMW, Ford, and Porsche, for their innovation in materials, expertise in lightweight structural design, and accelerated adoption in electrification programs.

Battery Enclosures & Structural Components

Constellium provides both rolled and extrusion-based aluminum materials—using 3xxx, 5xxx, and 6xxx-series alloys—that deliver strength, crash resistance, and thermal performance for pack structures and cell-to-pack designs.

Thermal Cooling Plates

Featuring thermal conductivity approximately five times that of steel, Constellium’s aluminum cooling plates support fast charging and heat management while enhancing battery longevity.

Busbars, Connectors & Cell Foils

Their aluminum busbars and connectors provide lightweight electrical pathways with excellent conductivity, formability, and corrosion resistance, while their foilstock for cathode layers offers high-performance, scalable solutions for cell production.

ALIVE: Lightweight Enclosure Innovation

Through the ALIVE (Aluminium Intensive Vehicle Enclosures) project, Constellium has worked with BMW, Volvo, and others to deliver battery enclosures that are 12–35% lighter than conventional designs while meeting crash, intrusion, and fire standards—all enabled via optimized alloy design and modular manufacturing.

Sustainability & Circular Aluminum Leadership

Aluminum’s recyclability—requiring 95% less energy to remelt—and Constellium’s certification under the Aluminium Stewardship Initiative enable greener supply chains. Constellium also invests in closed-loop recycling and low-carbon casthouses to reduce overall vehicle CO₂ footprints.

From cathode foil to full structural enclosures, Constellium’s aluminum solutions are embedded across EV battery architectures—enabling lighter, safer, and longer-range platforms.

As a collaborative R&D partner, Constellium helps OEMs co-engineer high-performance alloys, validate designs, and scale production while maximizing efficiency, safety, and sustainability.